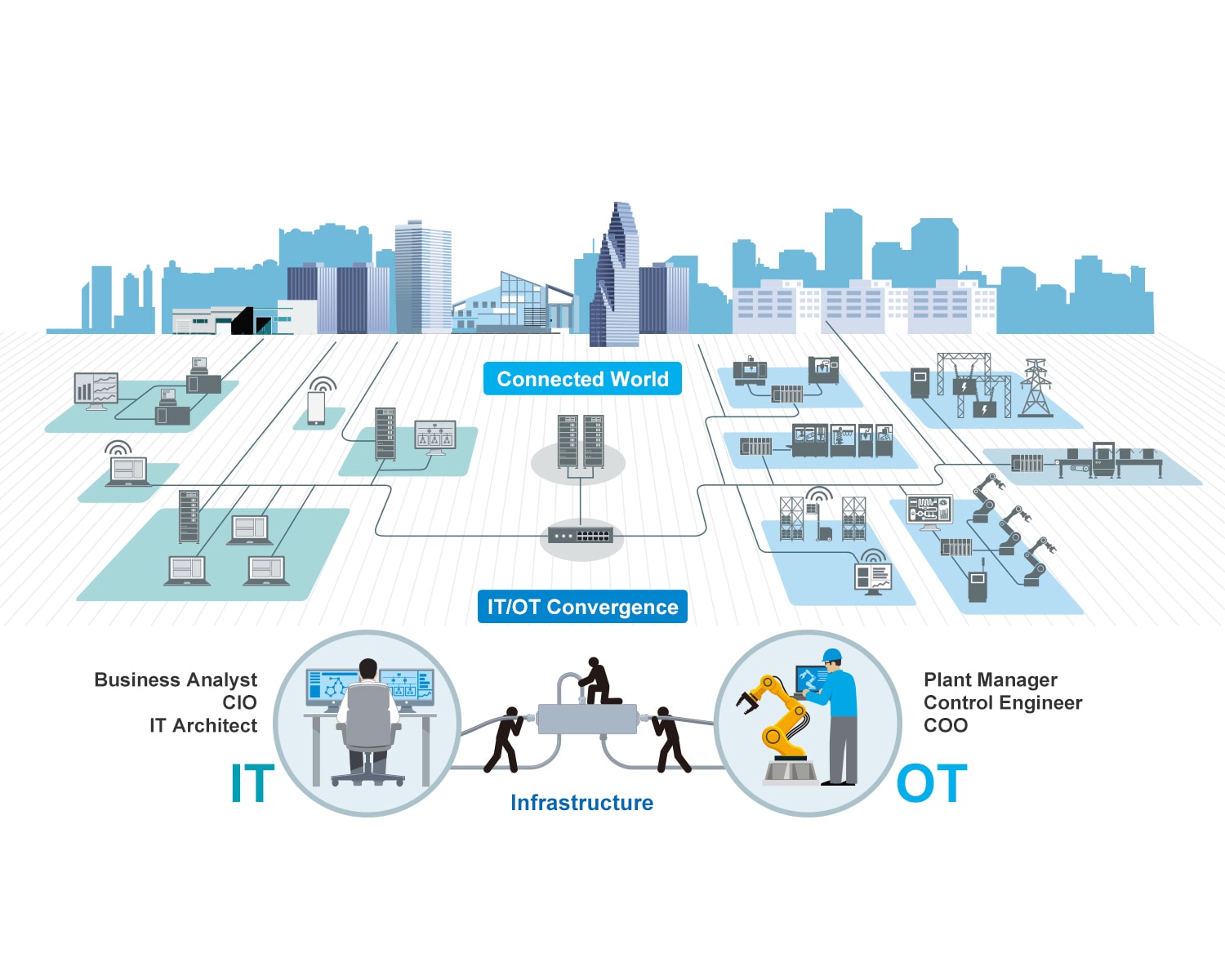

Simplify Connectivity for Smart Manufacturing

Connect to Remote Monitoring:

Address the challenges of connecting a large variety of subsystems and machines to perform remote monitoring

Real-time KPIs and dashboards, displaying accurate data on shop-floor operations, give managers valuable insights as to when and where they need to adjust their production planning. Therefore, a resilient and reliable network that connects a large number of existing data sources from various systems is critical. Find out how to address the challenges in connecting various systems and managing large networks to perform remote monitoring.

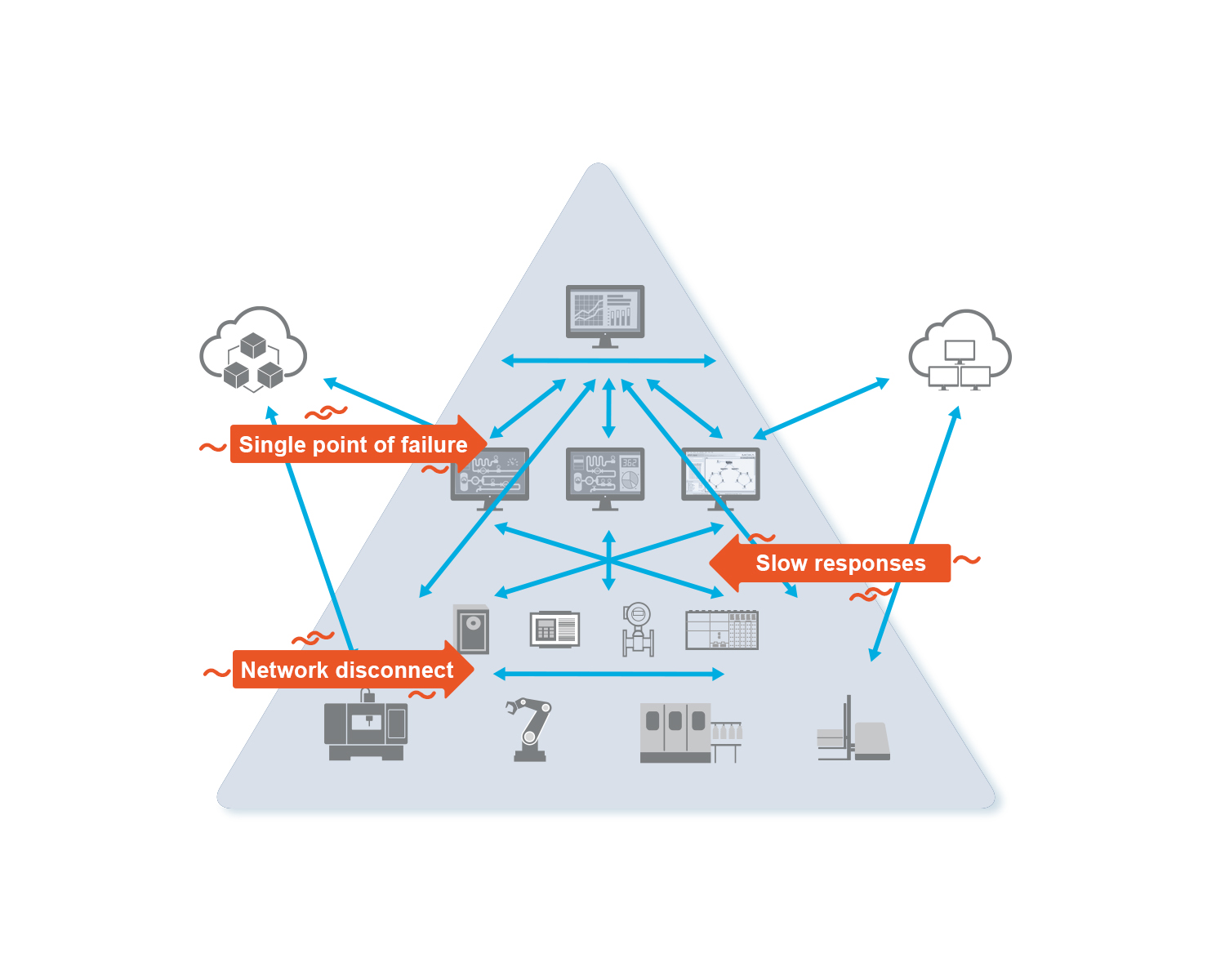

1 .1 Connecting Various Systems Causes Network Outage

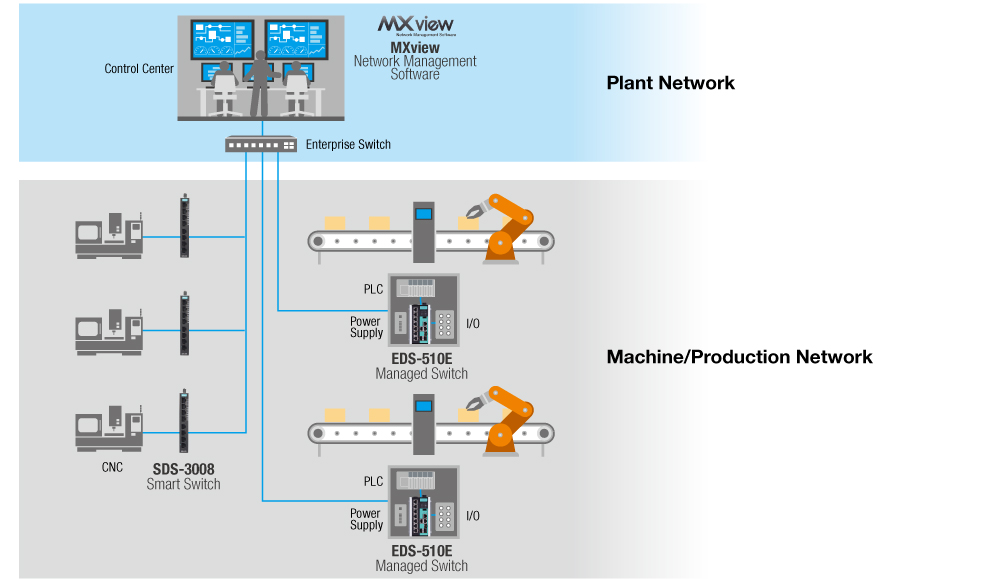

Connecting all the different OT subsystems makes the manufacturing processes transparent to managers. However, an interconnected network can become unstable or cause entire network outages—even though those systems have worked perfectly independently before. What if we can simplify network reliability to connect your various systems?

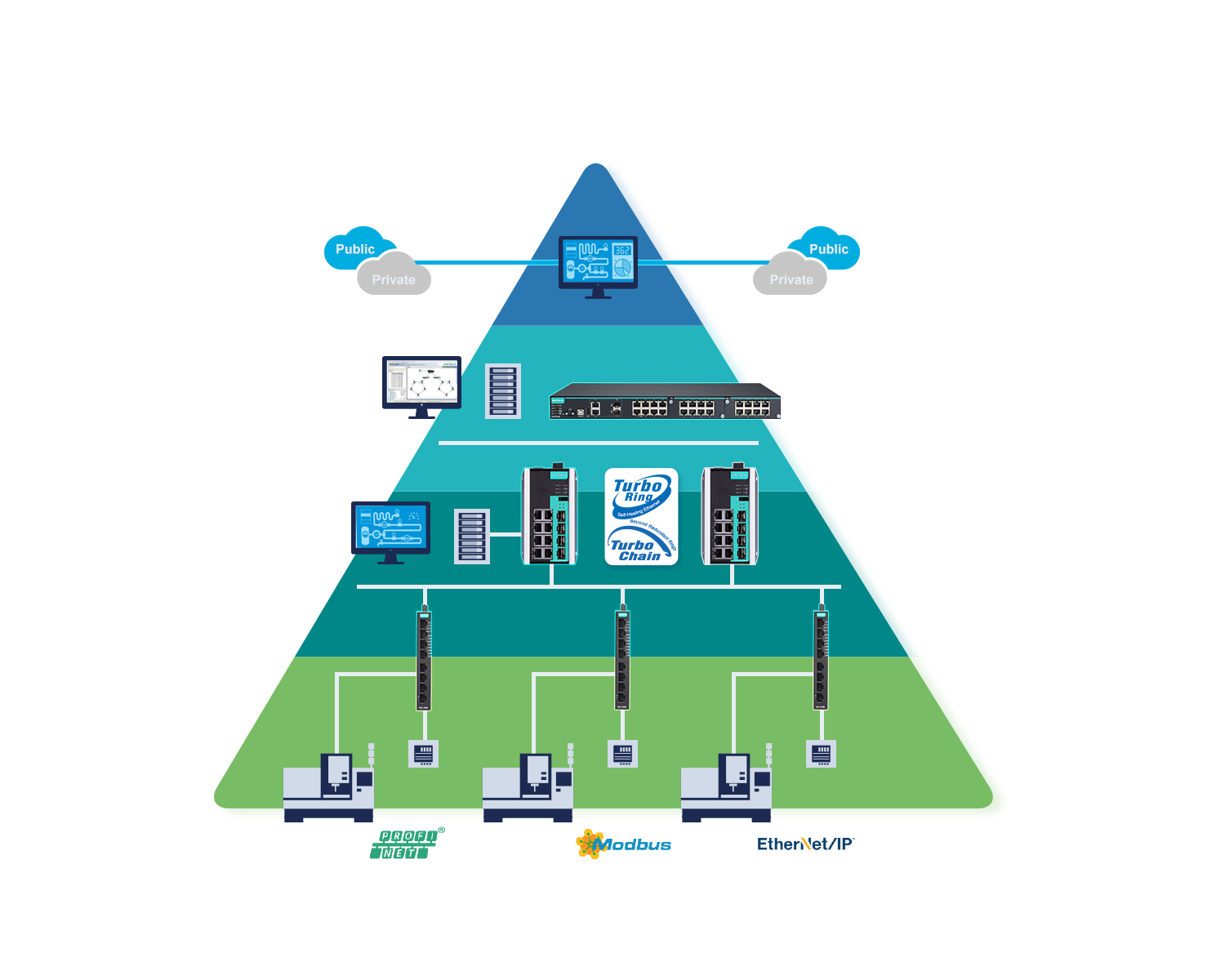

IIoT Connectivity:

Connecting different subsystems that consist of commercial and industrial network devices

Simplified:

Using industrial-grade network devices for cross-platform systems

Case Study

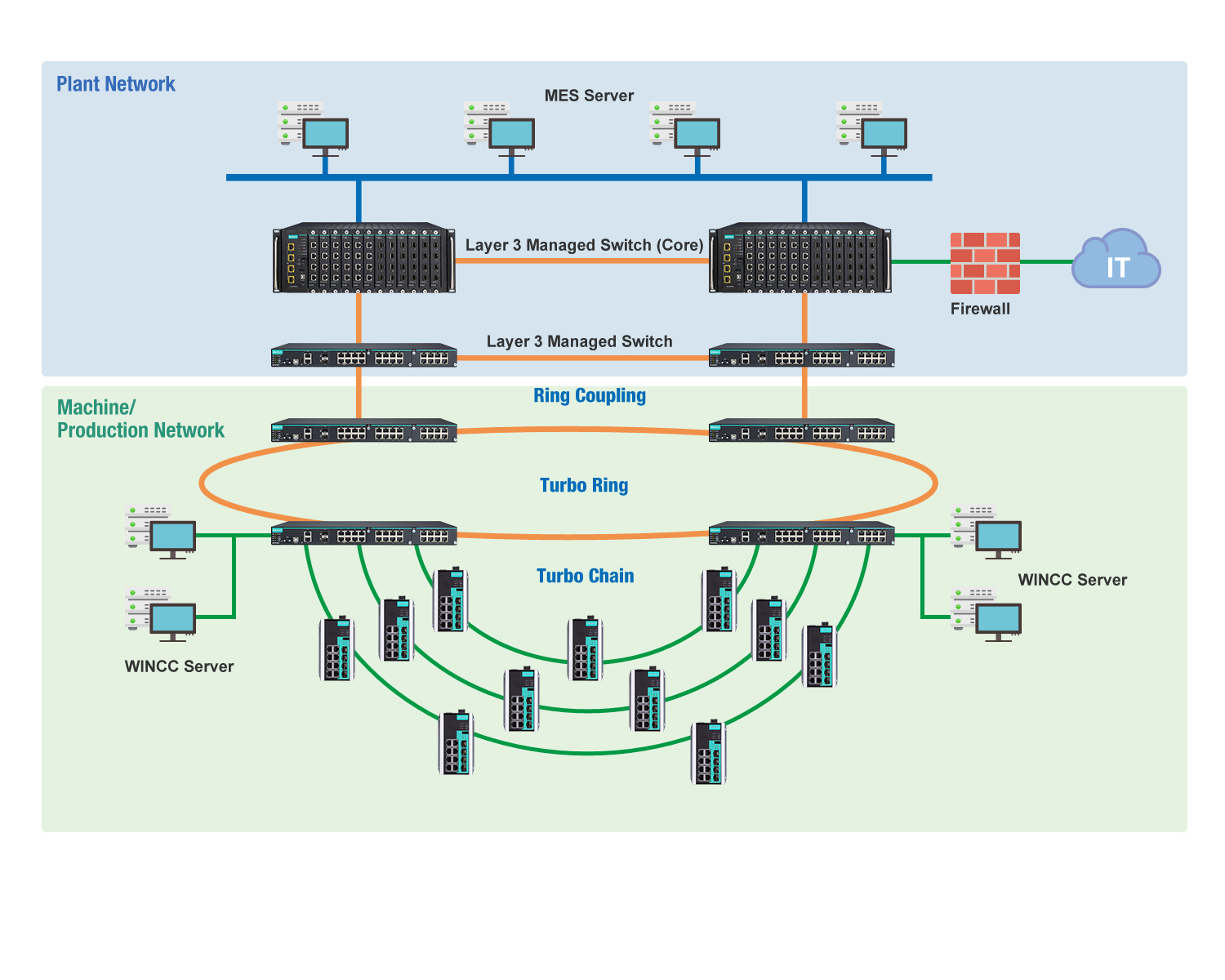

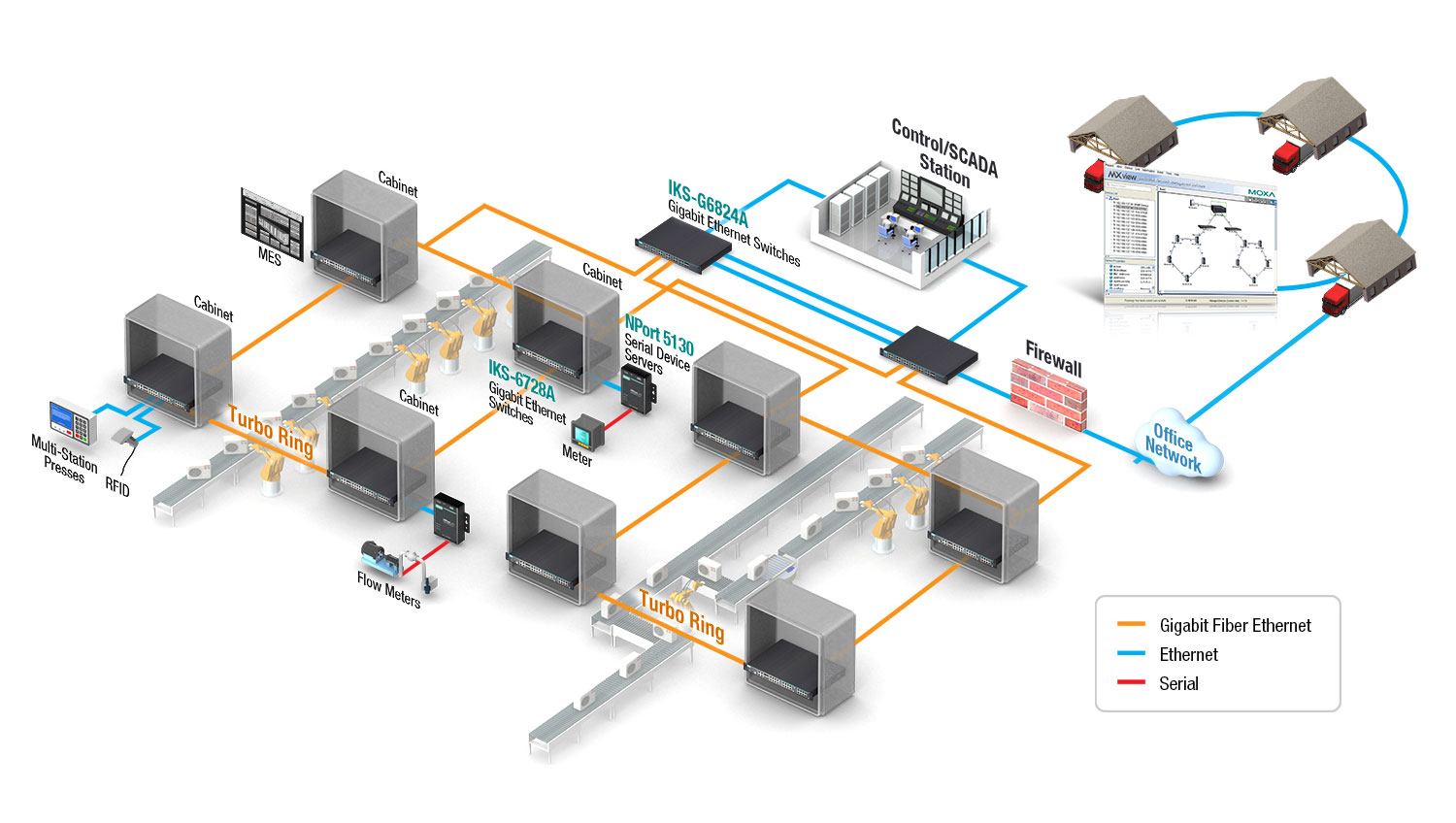

Managing a Large-scale Network in an Interconnected Factory: A leading home appliance manufacturer has built an interconnected factory, which involves a multitude of connections between smart machines and production lines at multiple sites. To ensure seamless data transmission between production lines and back-end MES and ERP systems, reliable network connectivity was required, so they adopted our industrial network management software to monitor the industrial Ethernet switches to diagnose and pinpoint failures in a large-scale network easily.

Recommended Products

Industrial Managed Ethernet Switch Portfolio

simplifies your network reliability for cross-platform systems

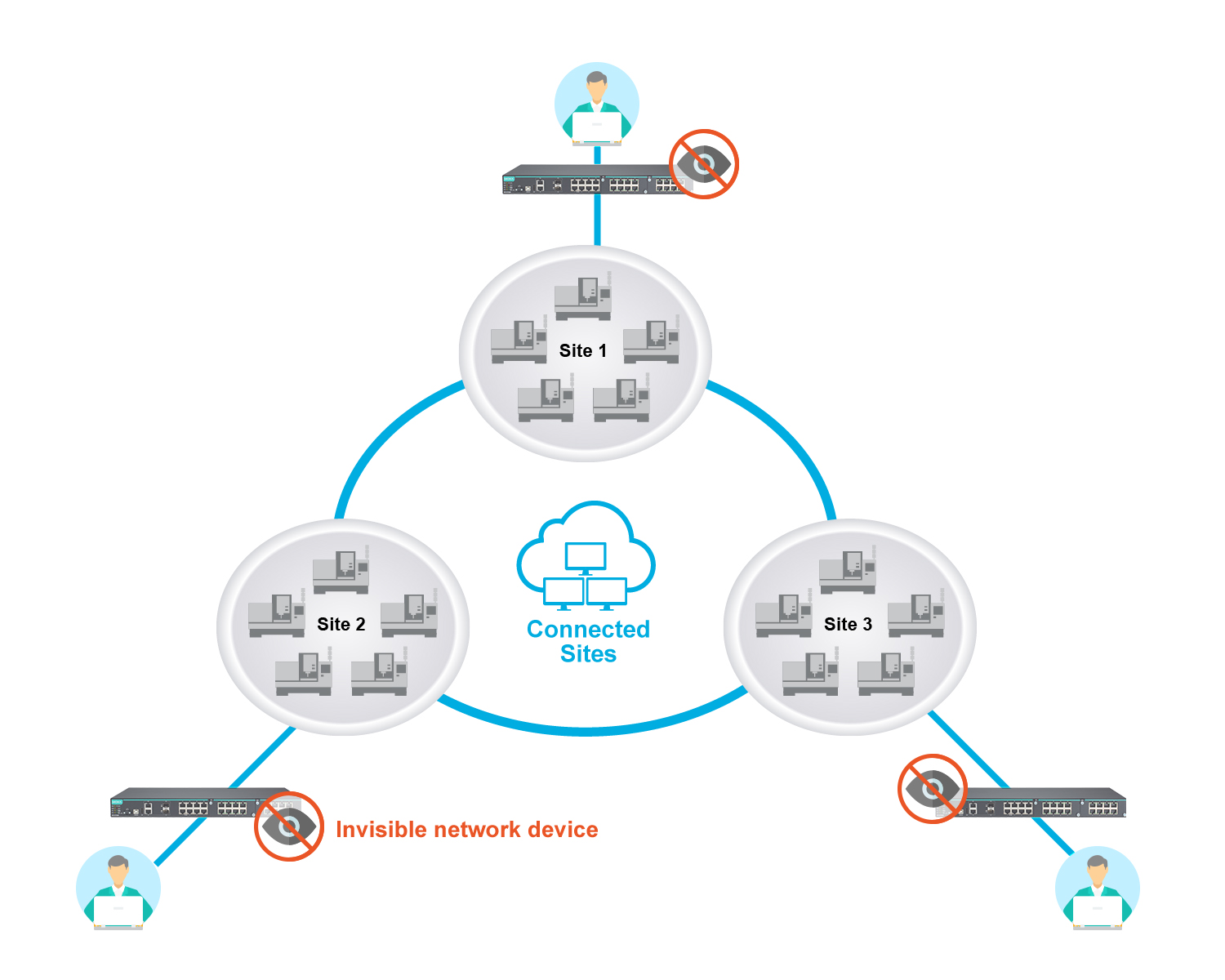

1.2 Invisible Large Networks Mean Unreliable Networks

Seeing the performance data of your production equipment can ensure operational reliability. At the same time, the visibility of network devices is just as important as production machines to maintain reliable and efficient factory operations. What if we can simplify your network management on a large scale?

IIoT Connectivity:

Connecting thousands of network devices in one network

Simplified:

Visualizes network devices to ensure operational reliability

Case Study

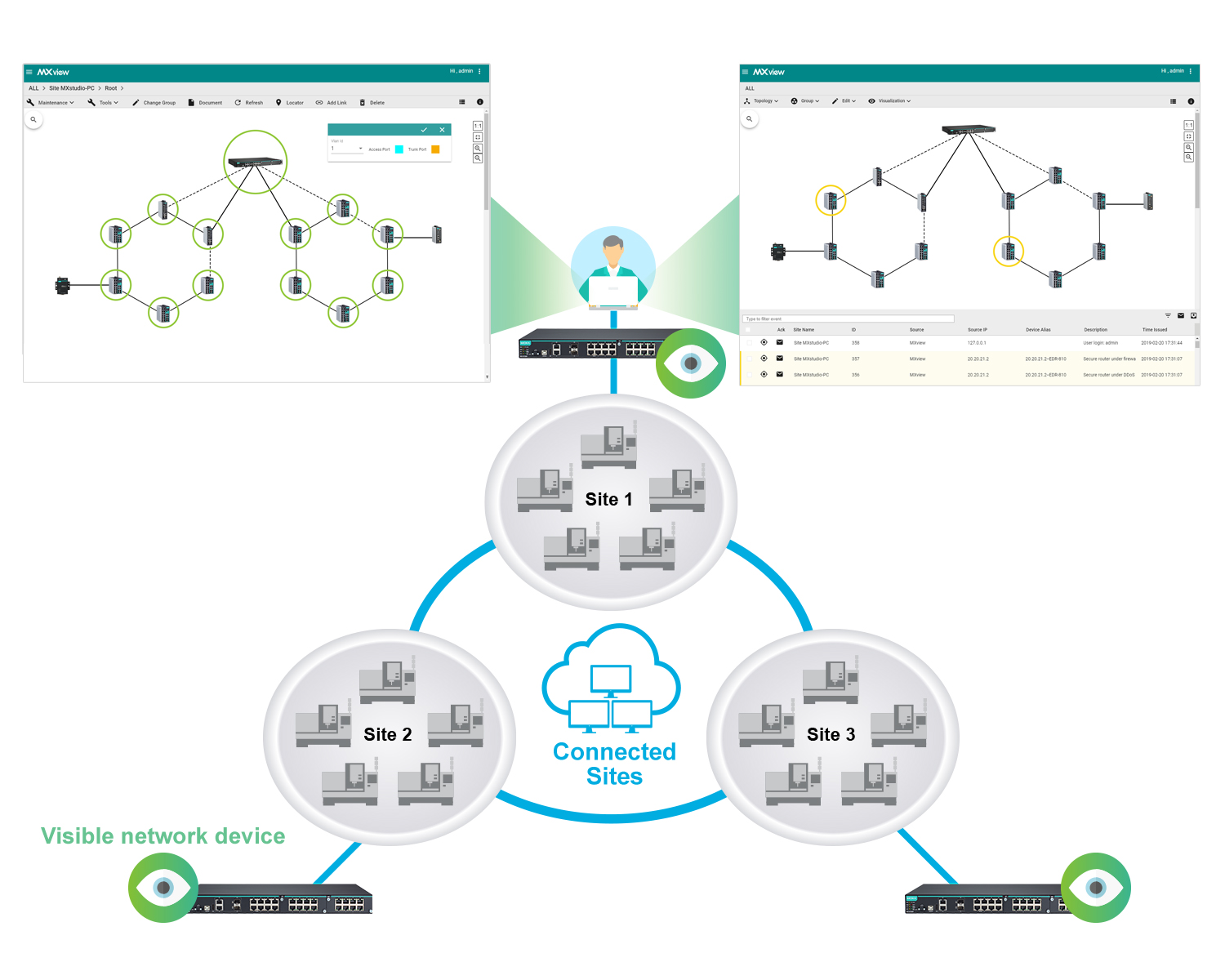

Managing a Large-scale Network in an Interconnected Factory: A leading home appliance manufacturer has built an interconnected factory, which involves a multitude of connections between smart machines and production lines at multiple sites. To ensure seamless data transmission between production lines and back-end MES and ERP systems, reliable network connectivity was required, so they adopted our industrial network management software to monitor the industrial Ethernet switches to diagnose and pinpoint failures in a large-scale network easily.

Recommended Products

Industrial Network Management Software

realizes large-scale network management with IT/OT systems that you prefer

Connect to Predictive Maintenance

Address the challenges of acquiring and preprocessing diverse data to perform predictive maintenance

To achieve optimized results for predictive maintenance, it is critical to leverage edge computing capabilities to preprocess data from a diverse set of data sources. This data is acquired through a variety of sensors added to key components. Managers can implement appropriate measures quickly, be prepared for any event, and autonomously perform maintenance before machine failure occurs. Find out how to address the challenges in performing diverse data acquisition and deploying edge intelligence for predictive maintenance.

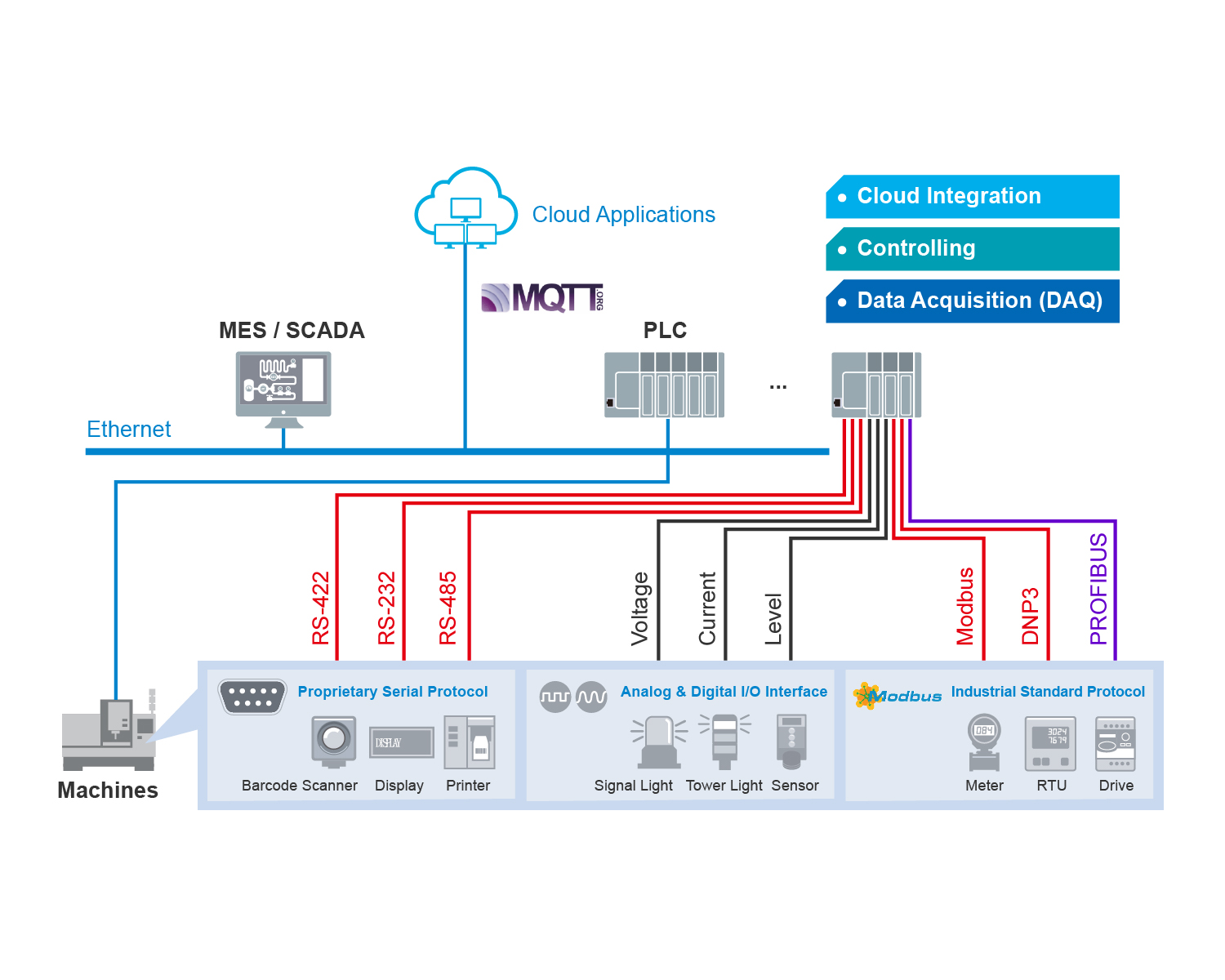

2.1 Diverse Data Acquisition Makes Connectivity Complex

Adding more sensors near key components to acquire big data can increase predictive accuracy. However, data acquisition gets complicated because of the large number of different protocols and interfaces used by the different sensors. What if we can simplify your diverse data acquisition?

IIoT Connectivity:

Connecting different sensors with different interfaces and protocols

Simplified:

Visualizes network devices to ensure operational reliability

Recommended Products

Serial Device Servers

simplify connectivity from serial to the cloud

Industrial Protocol Gateways

simplify converting standard protocols to the cloud

Modular Remote I/O

simplify connectivity from I/O to the cloud

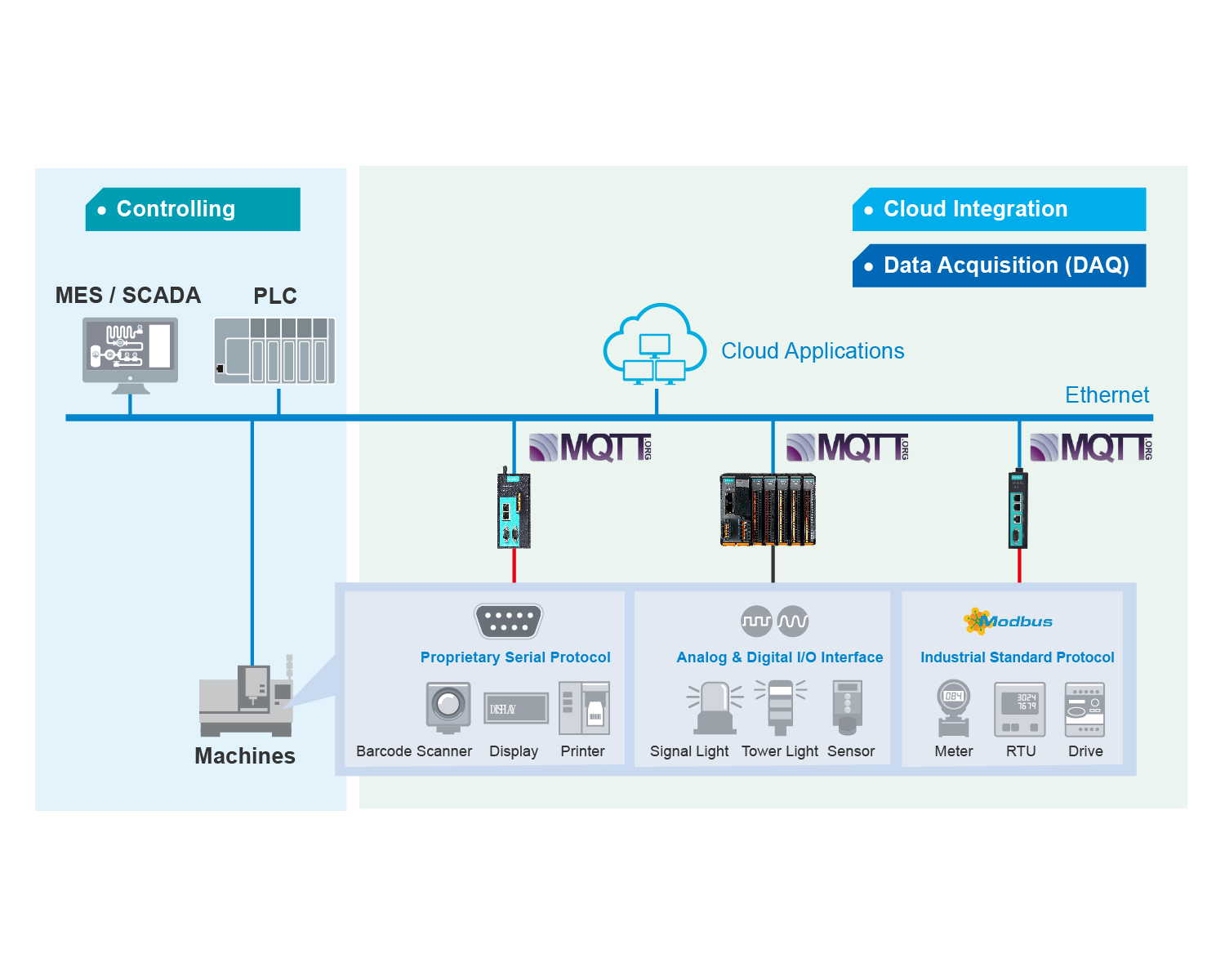

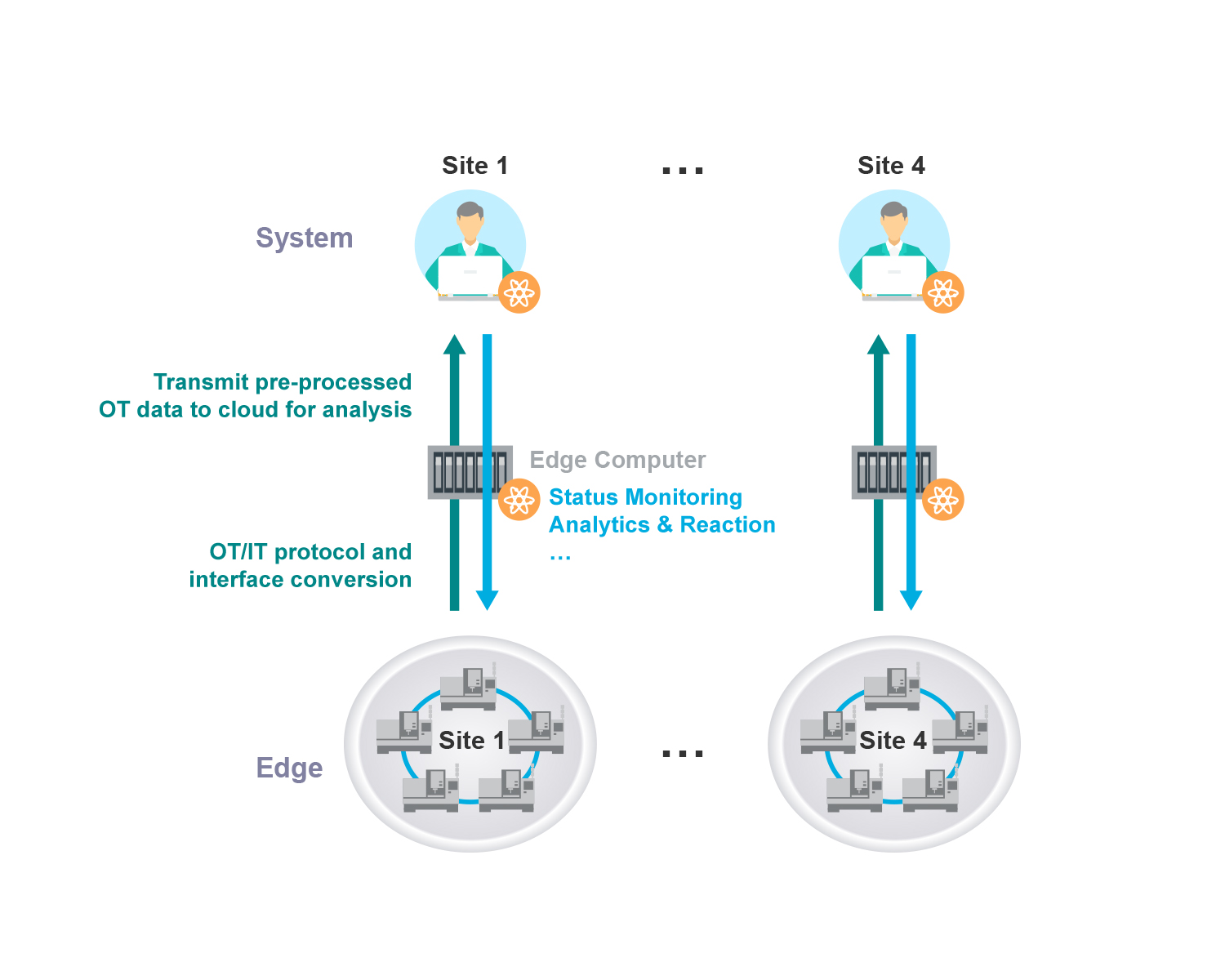

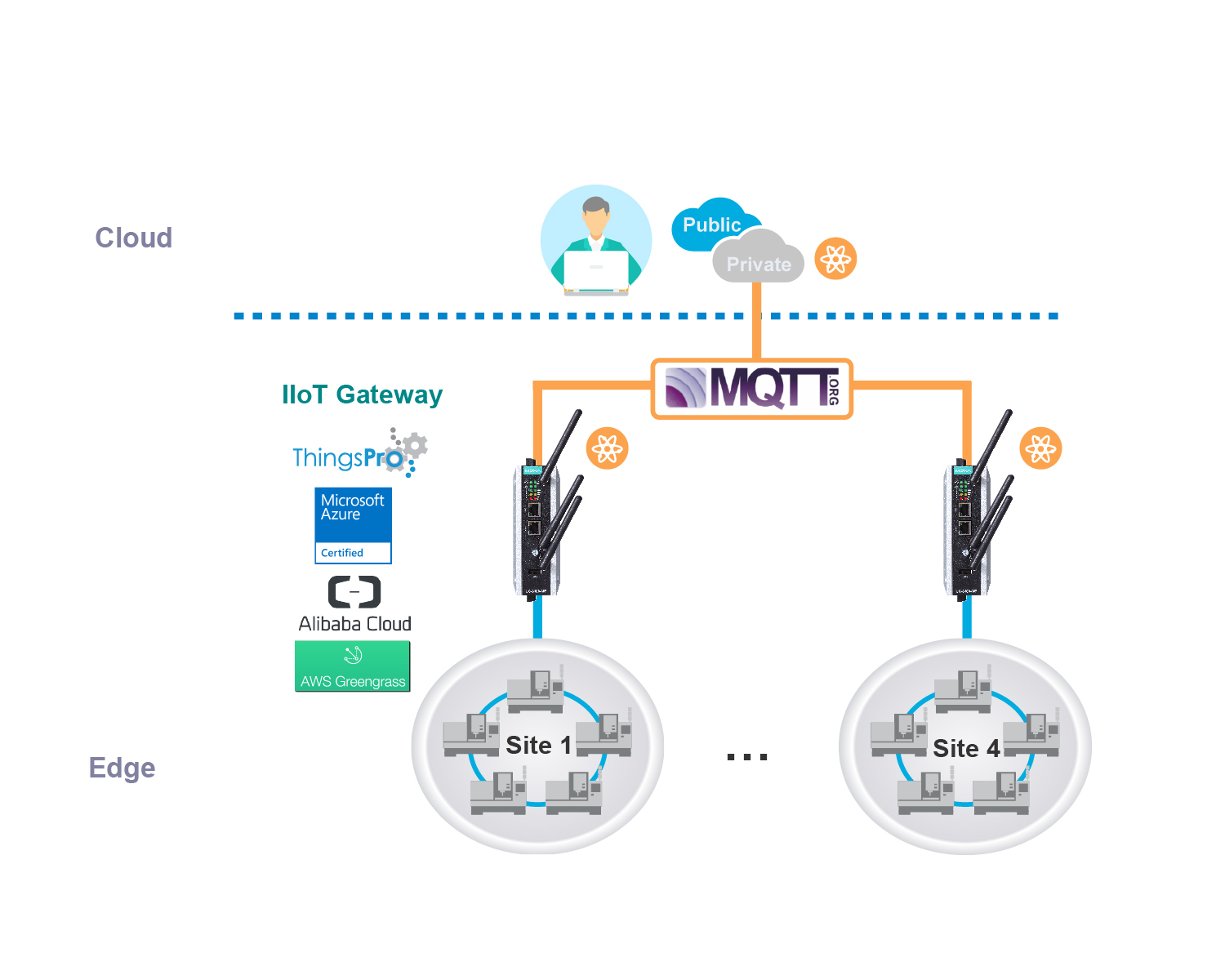

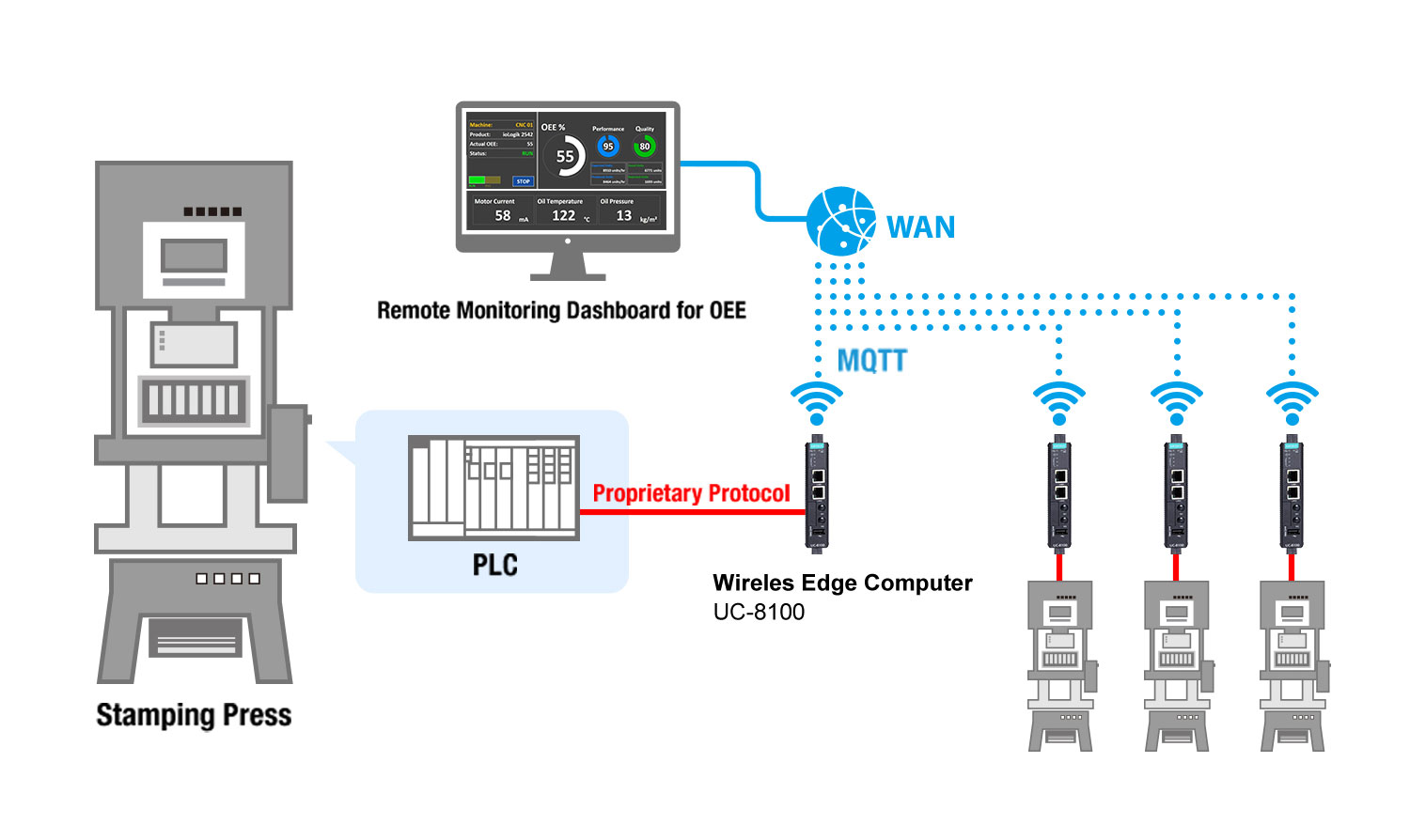

2.2 Deploying Edge Intelligence Is Hard to Start With

Sending all raw sensor data to the cloud is the best approach to do predictive

analysis. However, deploying edge computing in multiple sites for data preprocessing saves you more

on network bandwidth and allows you to anticipate and preempt machine failure. What if we can

simplify your large-scale edge computing deployment?

IIoT Connectivity:

Deploying edge computing at each site

Simplified:

Easy distribution of cloud technology to the edge in large-scale applications

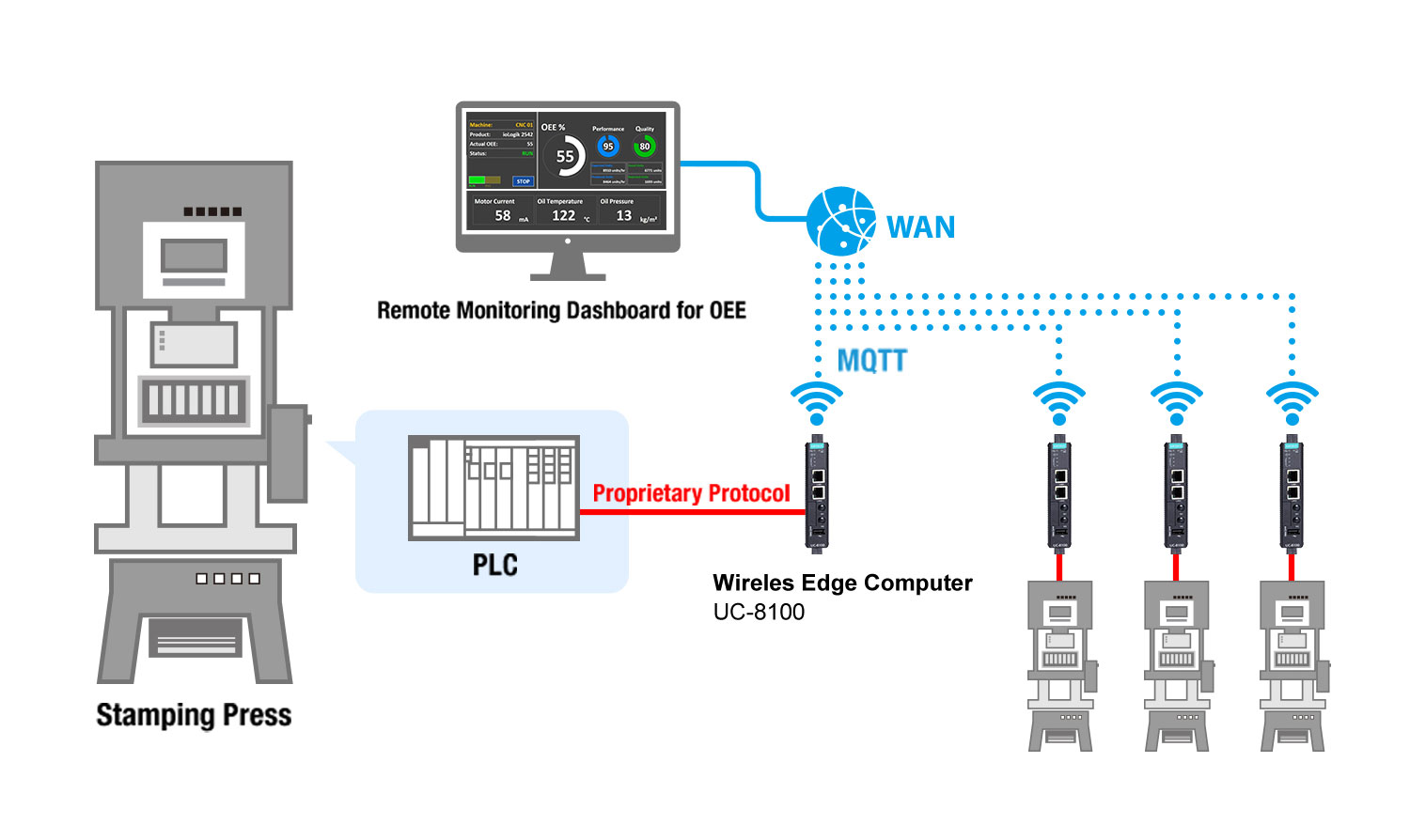

Case Study

Machine Data Acquisition through PLCs for Machine Tool Builders: Traditional machine tool builders are now willing to invest in new IIoT trends so that they can add more value to their products and improve the quality of their post-sales management and services. The UC-8100 Series embedded computer collects proprietary machine status data from different brands of PLCs (e.g., Mitsubishi, Delta, and Allen-Bradley), sends the data to the backstage control server, and displays the data on a dashboard remotely and locally.

Recommended Products

Cloud-ready IIoT Edge Gateways

simplify your large-scale computing deployment with a web GUI

Connect to Mass Customization:

Address the challenges of enabling a secure network to meet interconnected mass

customization needs

To achieve an uninterrupted manufacturing process that meets the demands of mass

customization, reducing downtime is critical in this type of fully automated and connected

manufacturing process. The ability to efficiently upgrade, troubleshoot, and maintain multiple

machines remotely is key to preventing downtime. Protecting connected machines from internal and

external threats is another key consideration. Find out how to address the challenges of performing

remote maintenance and guaranteeing IT-OT security collaboration for mass customization.

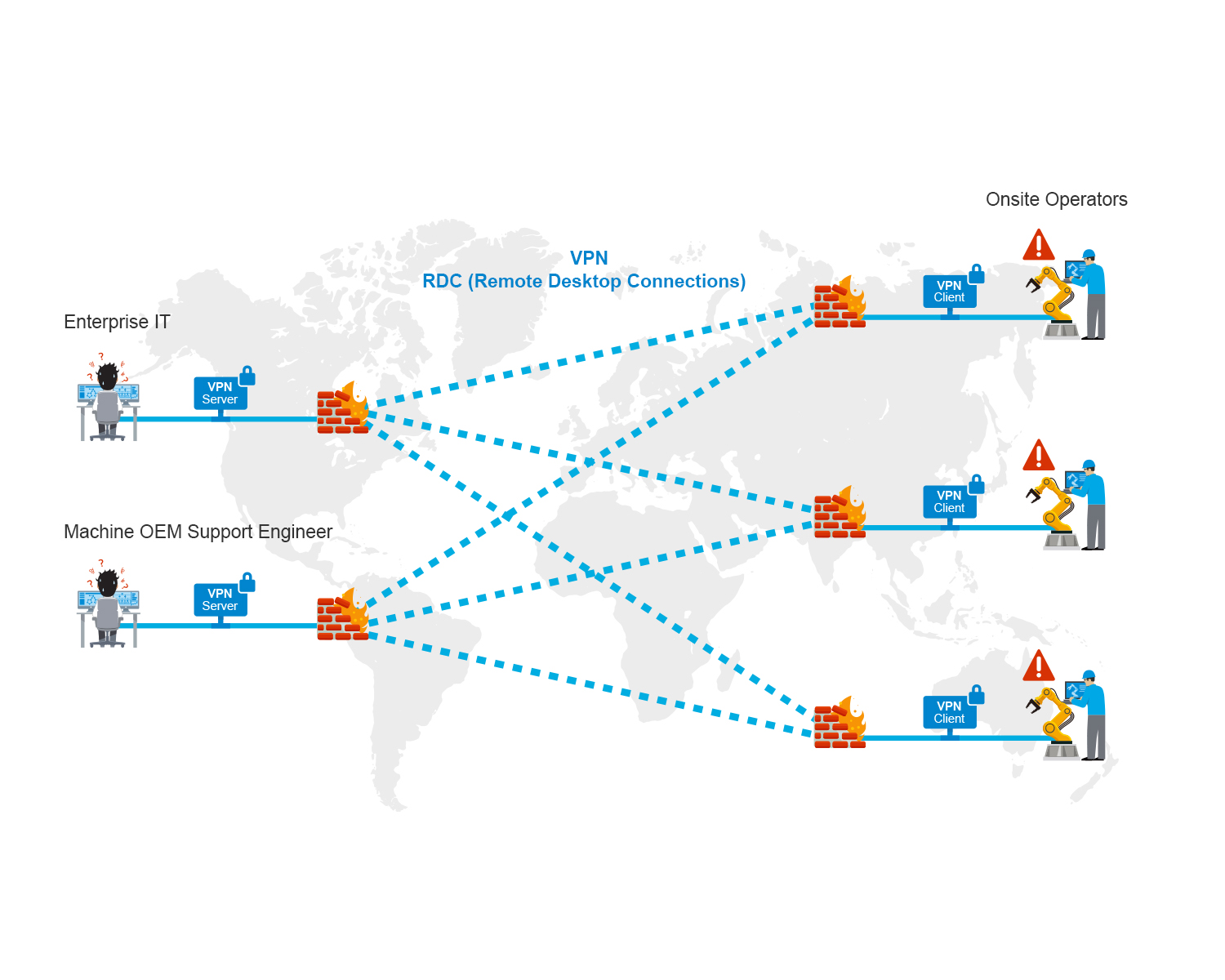

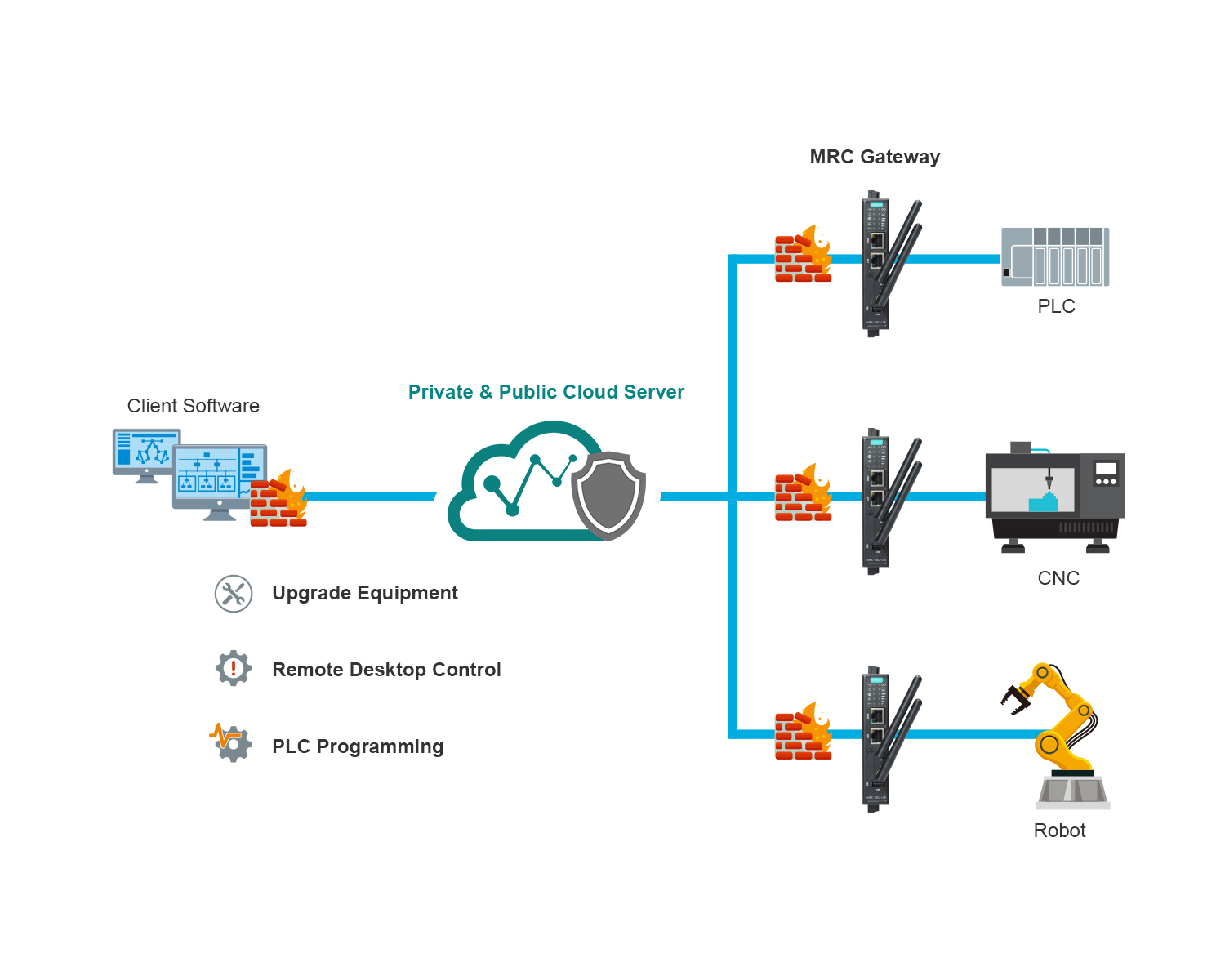

3.1 Establishing Multiple Secure Access Is Time-Consuming

Remotely accessing multiple machines to upgrade, troubleshoot, and maintain them can reduce unexpected downtime. However, establishing multiple secure connections for machines distributed in a large-scale application via traditional VPN and RDC (Remote Desktop Connections) methods is time-consuming and complex. What if we can simplify your remote connections in large-scale deployments?

IIoT Connectivity:

Using VPN/RDC to establish multiple secure remote connections

Simplified:

Case Study

Secure Remote Access for Improved Machinery Services: Maximizing network uptime enhances machine productivity. Therefore, a Taiwan machine builder wanted to work closer with its worldwide customers to realize predictive maintenance applications remotely, so it installed remote access software on IIoT gateways to build secure connections between engineers and machines without an add-on computer. The bonus was that the software did not require extensive IT expertise for both engineers and machine operators..

Recommended Products

Remote Connection Management Platform

simplifies your secure remote access and control in large-scale deployments

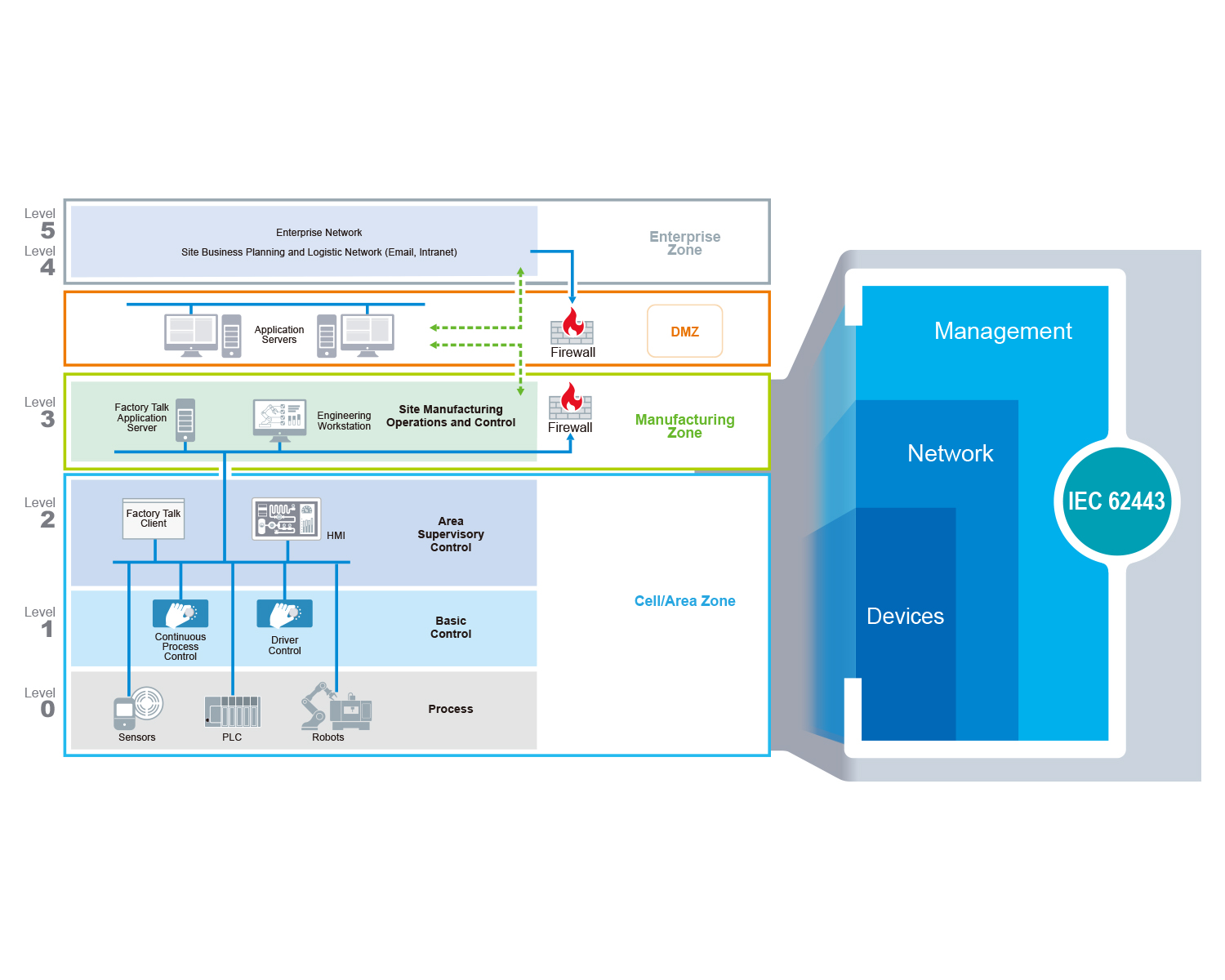

3.2 Overcoming Security Silos for Interconnected Systems

Remotely accessing multiple machines to upgrade, troubleshoot, and maintain them can reduce unexpected downtime. However, establishing multiple secure connections for machines distributed in a large-scale application via traditional VPN and RDC (Remote Desktop Connections) methods is time-consuming and complex. What if we can simplify your remote connections in large-scale deployments?

IIoT Connectivity:

Simplified:

Case Study

Visualize the Security Status of Large-scale Factory Networks: An automotive parts plant manager planned to digitalize their production processes. The field devices ran on the EtherNet/IP protocol for control unification and data acquisition. As the network infrastructure in this plant was of a large scale, it was very difficult for the plant manager to monitor all devices and visualize the network topologies. To realize digitization, all networks were interconnected from the field site to the ERP and even to the cloud. It was essential to have good cybersecurity measures to allow this transformation to occur, without compromising production efficiency.

Recommended Products

Defense-in-Depth Cybersecurity

that includes secure devices, secure network infrastructure, and security management