Balluff Condition Monitoring ToolKit (CMTK) and Sensor BCM Generation 2

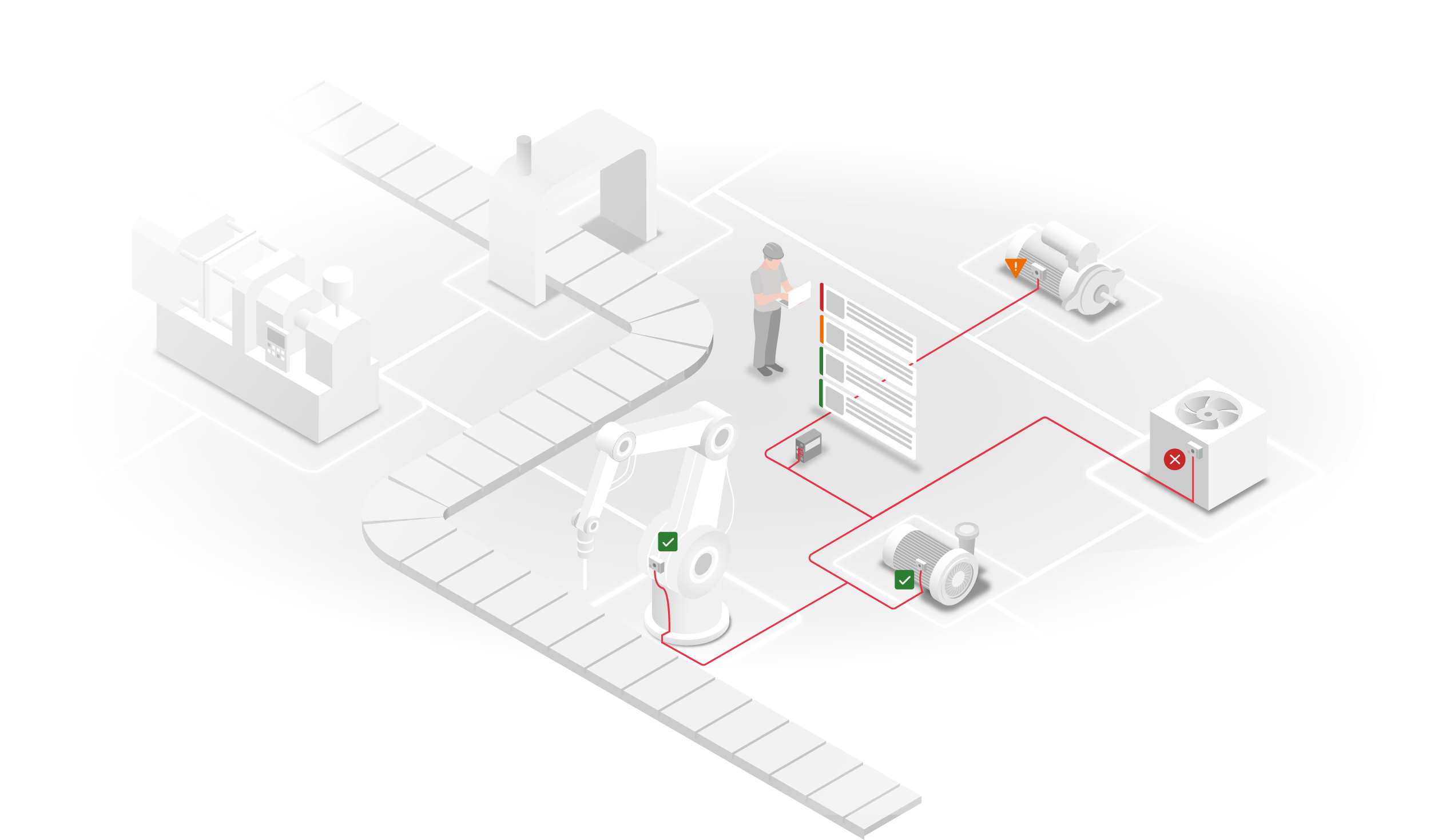

Imagine knowing at an early stage which machine or component in your plant could cause problems in the near future. It is possible, however, many existing plants do not have the technical prerequisites for condition monitoring, even though this can prevent unplanned downtime and unnecessary costs. Until now, the retrofitting of plants has often failed due to the high effort and the associated costs for the permanent monitoring of relevant machine and process parameters.

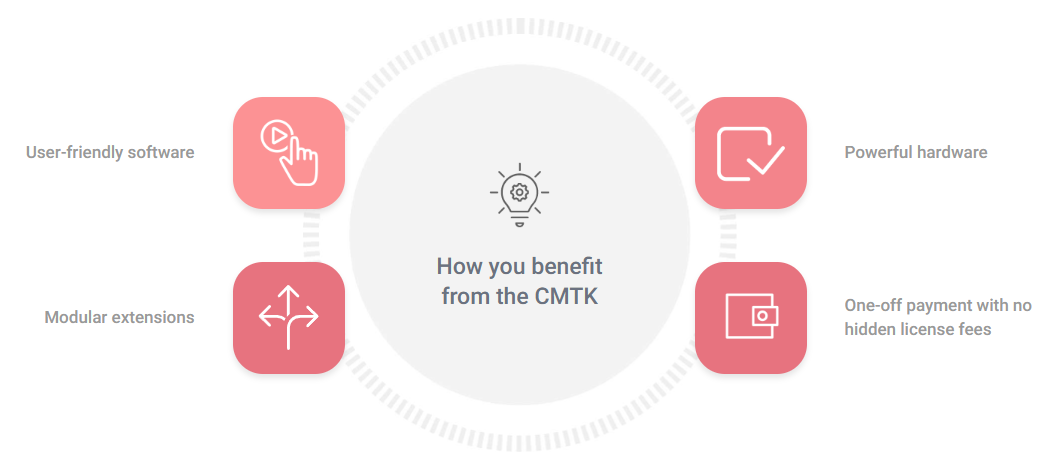

Here, the CMTK system represents a new and easy-to-implement solution with an excellent cost-benefit ratio. With the flexible CMTK system, you quickly gain deeper insights into the actual condition of your machines and systems and can, therefore, detect deviations and problems at an early stage. All components are perfectly matched to each other. High acquisition costs without added value are a thing of the past, because the CMTK is a complete system without hidden costs or cumbersome subscription models.

Features

- Unified retrofit solution for machine and process monitoring

- High flexibility through the connection of up to four arbitrary IO-Link sensors

- Plug-and-play commissioning of the system and visualization of the data

- Output of warning messages when adjustable limit values are exceeded

- Self-sufficient system with data storage – independent of cloud and machine control

- Remote monitoring from any location thanks to network integration

| Product type | IO-Link Edge Gateway |

|---|---|

| Value proposition | Risk-free integration of permanent condition monitoring increases the availability of machines and systems. |

| Application areas | Self-sufficient and connected: Operation of control-independent maintenance systems of a plant and data provisioning as part of larger IT structures, e.g. for digital twins. |

The challenges of operating machines and systems

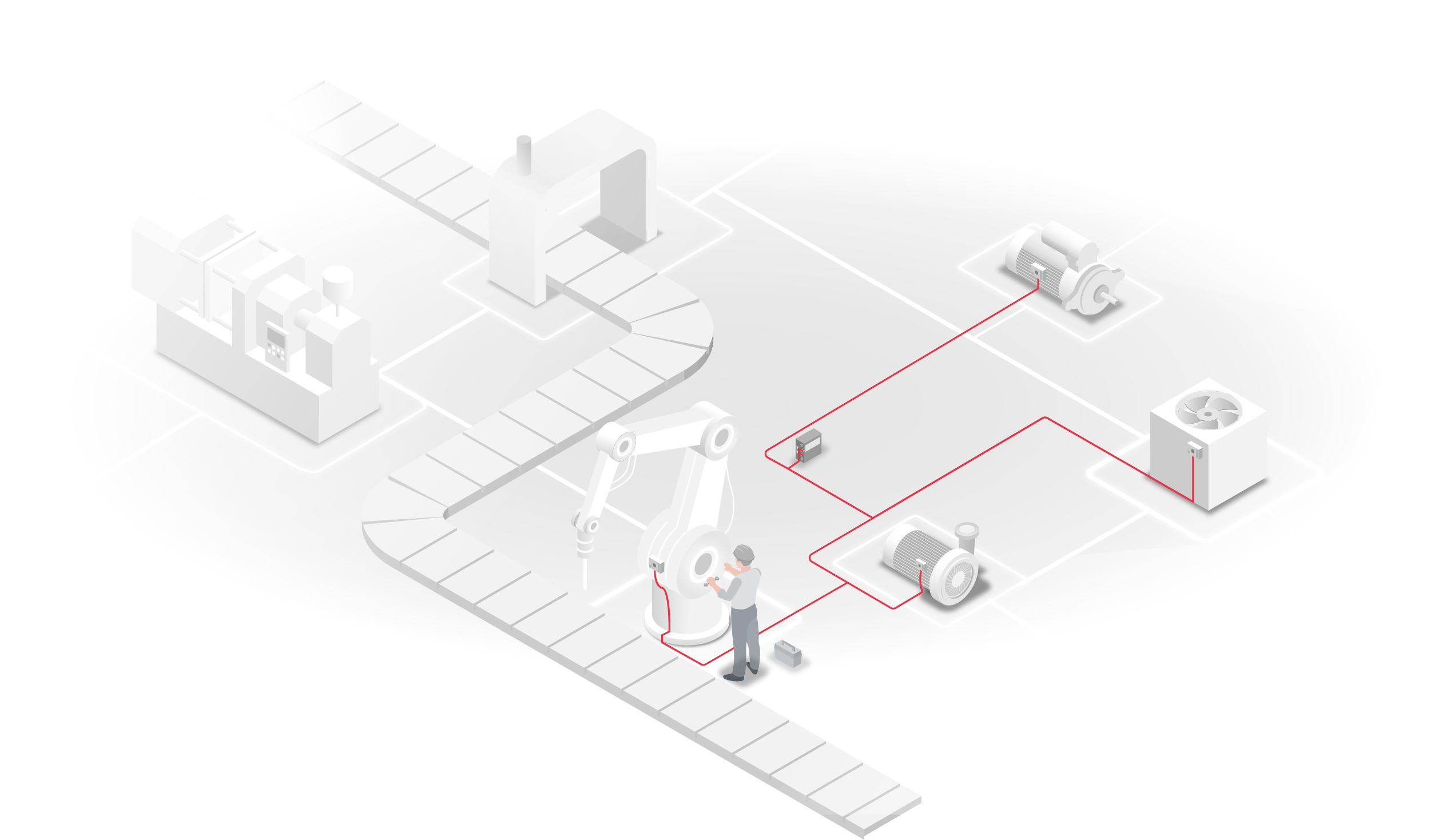

A major challenge in manufacturing is monitoring wear and tear on components of machines, systems or complex production lines. Different stresses lead to different degrees of wear on the parts, which affects their service life. In addition, factors such as operating and usage time, environmental conditions and the frequency of maintenance and repairs influence the load on the individual parts.

Condition monitoring

Enter the Condition Monitoring Toolkit (CMTK) , an innovative hardware unit, paired with intelligent software for automated data acquisition and evaluation. Connected IO-Link sensors seamlessly collect condition data without having to adapt your existing systems.

The condition monitoring quickly and reliably detects the smallest changes. This means you are always informed about the condition of your machines, can plan repairs and carry out preventive maintenance.

Find out more about condition monitoring

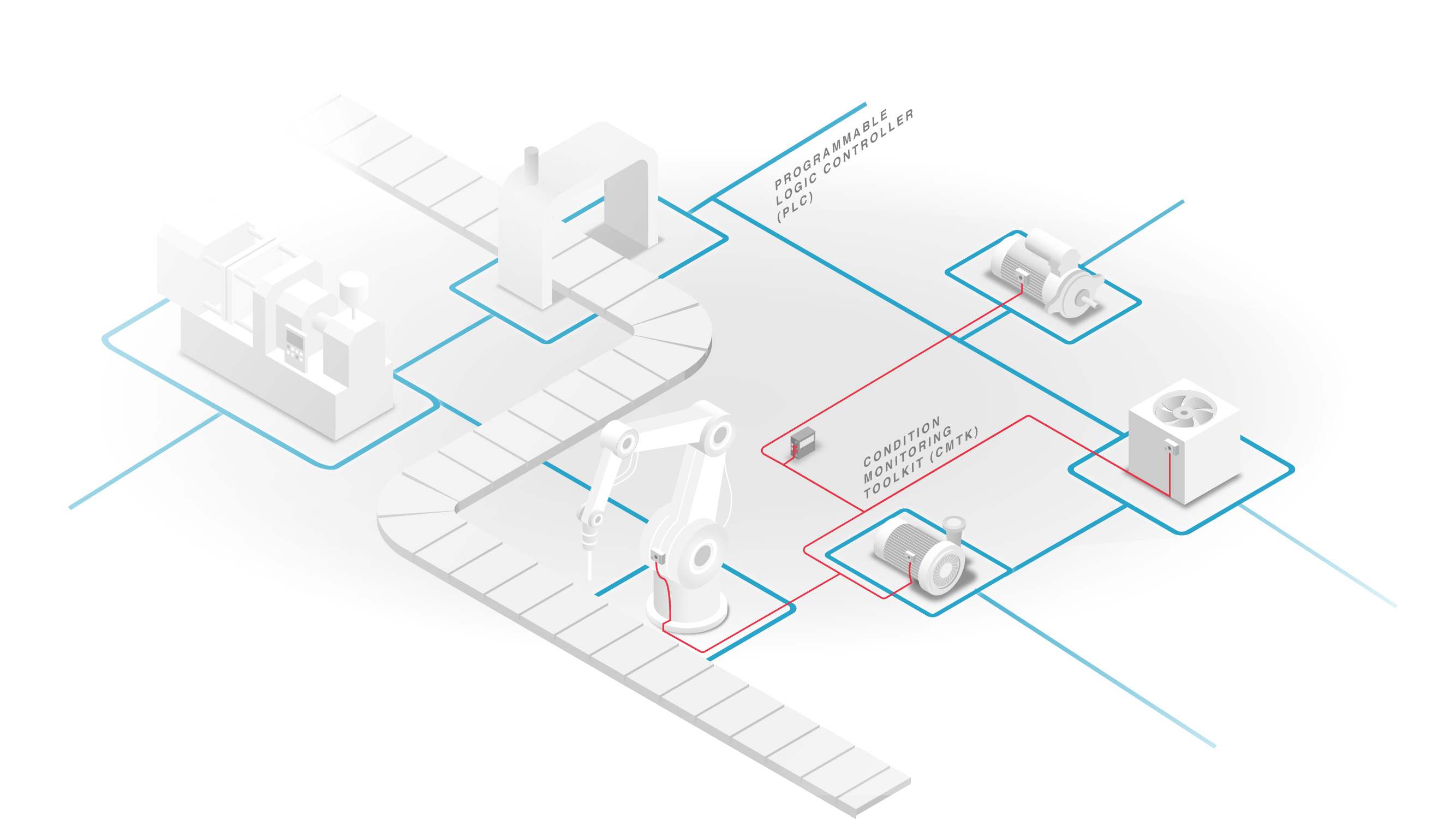

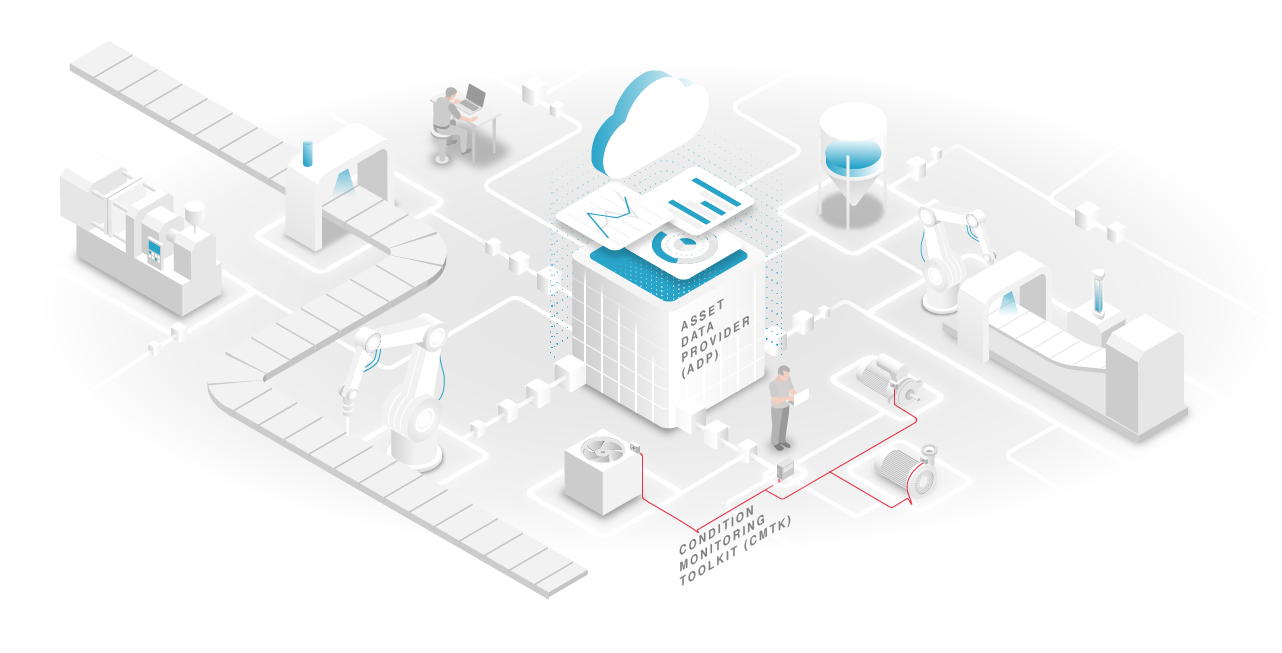

Self-sufficient infrastructure

The CMTK can operate completely independently of existing IT and automation networks in your facilities, reducing data traffic and creating minimal disruption to existing systems.

Plug-and-play commissioning

The CMTK is ready for immediate use without configuration. It can be optimally adapted to your needs with individual parameters, avoiding long downtimes.

Configuring separate notifications

Easily set up notifications when the sensor data indicates certain machine behavior and define monitoring tasks for different machine types.

Open scalability

Combine any number of CMTK devices into a network without additional configuration effort - and access them all from one digital interface, making the management and monitoring of your systems more efficient.

Expandability through digital formats

The CMTK provides its data via OPC/UA and MQTT so that you can process it over local networks or cloud systems.

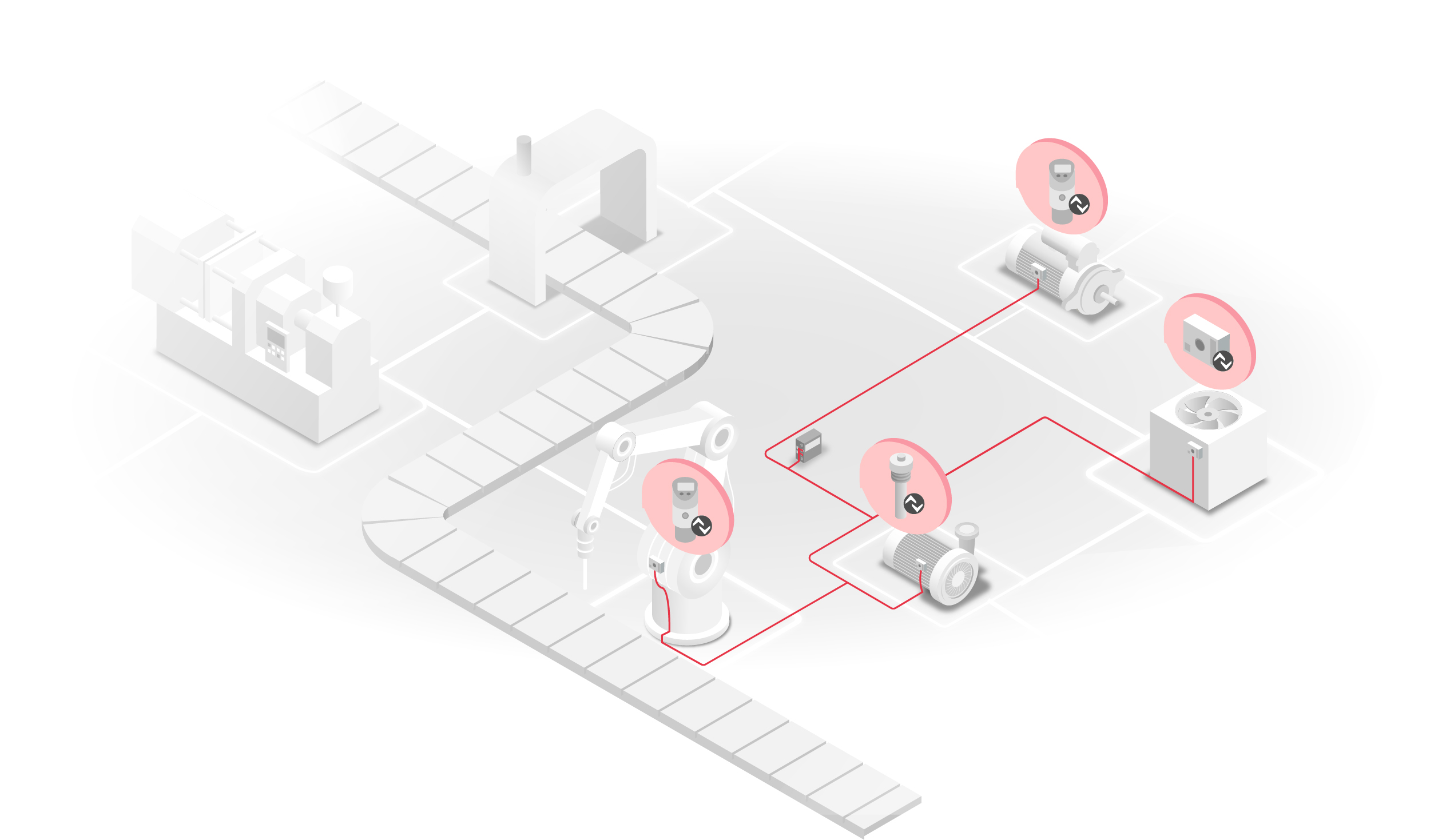

Ready compatibility with numerous sensors

Combine the CMTK with any number of IO-Link and condition monitoring sensors to obtain monitoring data on, for example, the vibration, temperature or pressure in your machines.

Applications and solutions

Temperature monitoring of industrial machines

Our sensors monitor the temperature important machine components. Access real-time data and track the condition of the machine.

Vibration monitoring of your machines and systems

Reliably detect warning signs such as excessive vibrations with our Condition Monitoring Toolkit and monitor electric motors, fans and machine tools with precision.

Reliably monitor electric motors

Use the CMTK as a complete retrofit solution to monitor electric motors and avoid unwanted and unplanned downtime.

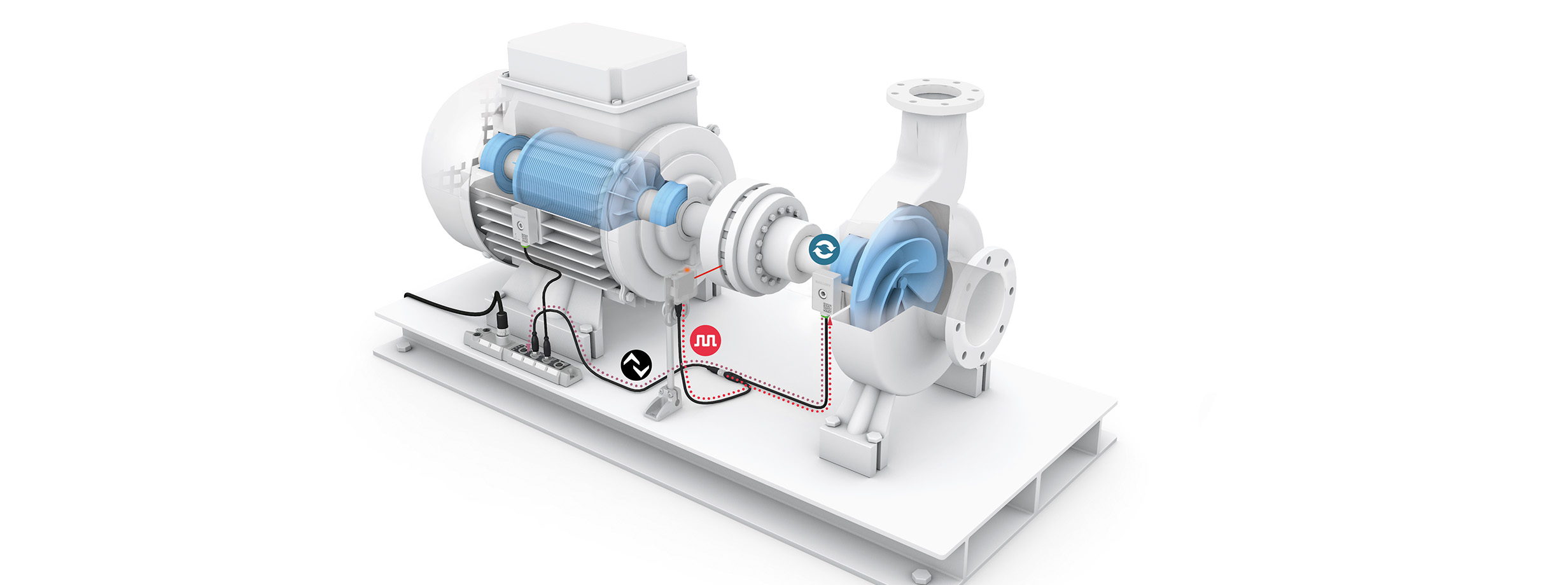

Pump monitoring to ensure operational safety

The CMTK checks that pumps, valves and tanks are working reliably and alerts you to any deviations. This increases operational reliability and saves you money.

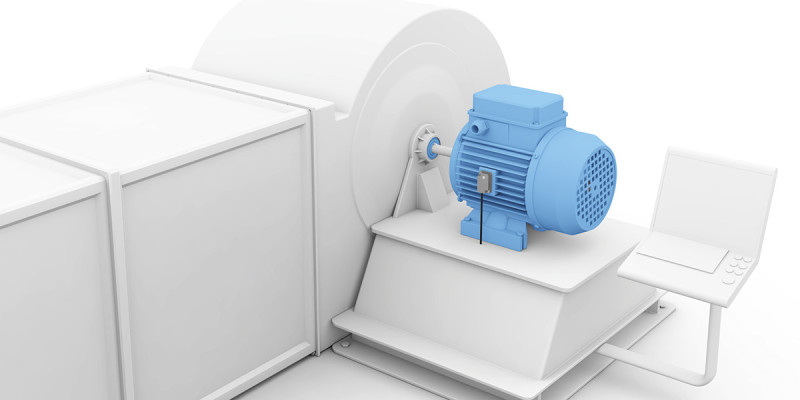

Reliable monitoring of fans and air systems

Monitor fans and exhaust systems with the CMTK to detect deviations at an early stage and avoid failures.

Keep an eye on hydraulic units at all times

Prevent costly production downtimes by simply monitoring hydraulic systems with our Toolkit.

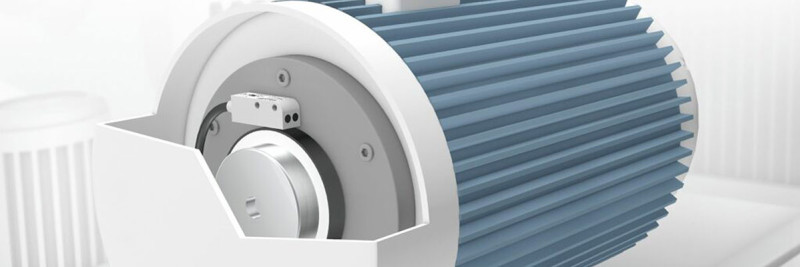

The new generation of BCM condition monitoring sensors

Advanced Analytics / Vibration & Temperature

Basic Analytics / Vibration & Temperature

BCM0003 – Advanced Analytics

| Function: | Vibration analysis in time domain & frequency range, Rotational speed input, Contact temperature monitoring |

| Vibration Frequency: | 2...4500 Hz (±10 %), 2...6000 Hz (±3 dB) |

| Axes: | 3 |

| Measuring Range: | -16…16 g |

| Temp Range: | -40…+80 °C |

| Voltage: | 24 V DC |

| Interface: | IO-Link 1.1.3 |

| Material: | Stainless steel 1.4404 (316L) |

| IP Rating: | IP67, IP68, IP69K |

| Ambient Temp: | -40…80 °C |

BCM0004 – Basic Analytics

| Function: | Vibration analysis in time domain, contact temperature monitoring |

| Vibration Frequency: | 2...4500 Hz (±10 %), 2...6000 Hz (±3 dB) |

| Axes: | 3 |

| Measuring Range: | -16…16 g |

| Temp Range: | -40…+80 °C |

| Voltage: | 24 V DC |

| Interface: | IO-Link 1.1.3 |

| Material: | Stainless steel 1.4404 (316L) |

| IP Rating: | IP67, IP68, IP69K |

| Ambient Temp: | -40…80 °C |

Sensors working together – Smart RPM input

The current RPM plays a decisive role in monitoring the condition of rotating components (e.g. rolling bearings, gear wheels). This information is particularly important for frequency-based pre-processing (FFT). The RPM can be continuously provided to the BCM via the machine control system. The problem is often - especially when retrofitting existing systems - that this option is not available. We therefore offer another alternative with the smart RPM input.

Networking modules

BAV002N

| Processor: | 1.8 GHz / 400 MHz |

| Working memory: | 2 GB RAM |

| Connection slots: | 2x LAN: RJ45-Female, 8-pin, 4x IO-Link: M8x1-Female, 4-pin, A-coded, PWR: Phoenix MC1.5/3-STF-3.81, USB: USB 2.0 Standard-A |

| Dimension: | 101 x 126 x 50 mm |

| Data storage: | 8 GB EMMC |

BNI00HP

| Interface: | PROFINET / EtherNet/IP |

| Interface IIoT: | REST API, MQTT |

| Auxiliary interfaces: | 8x IO-Link |

| Port-class: | Type A |

| Output current max.: | 0.25 A |

For any further information, please contact us via sales@manuauto.com.